Techinservice has supplied and supervised the installation of raw juice heater for a sugar refinery in Uelzen, the largest sugar factory of German group Nordzucker AG. The refinery capacity is 22 thousand tons of sugar beet per day.

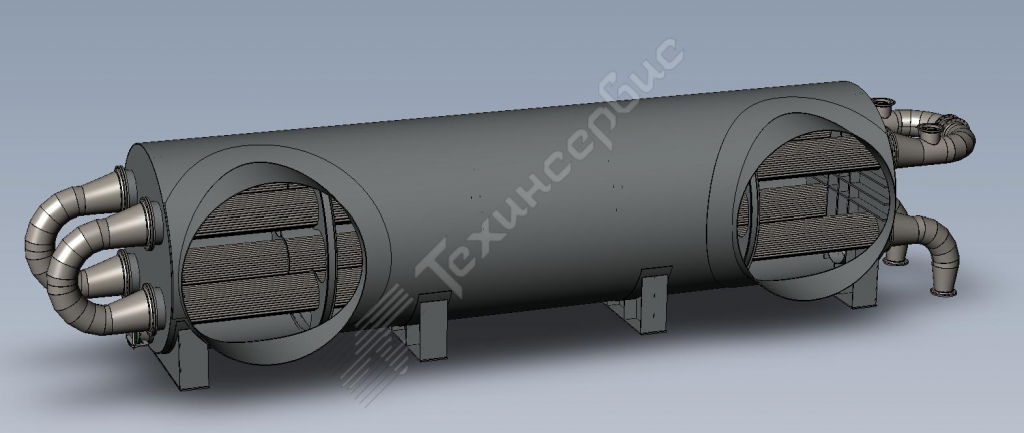

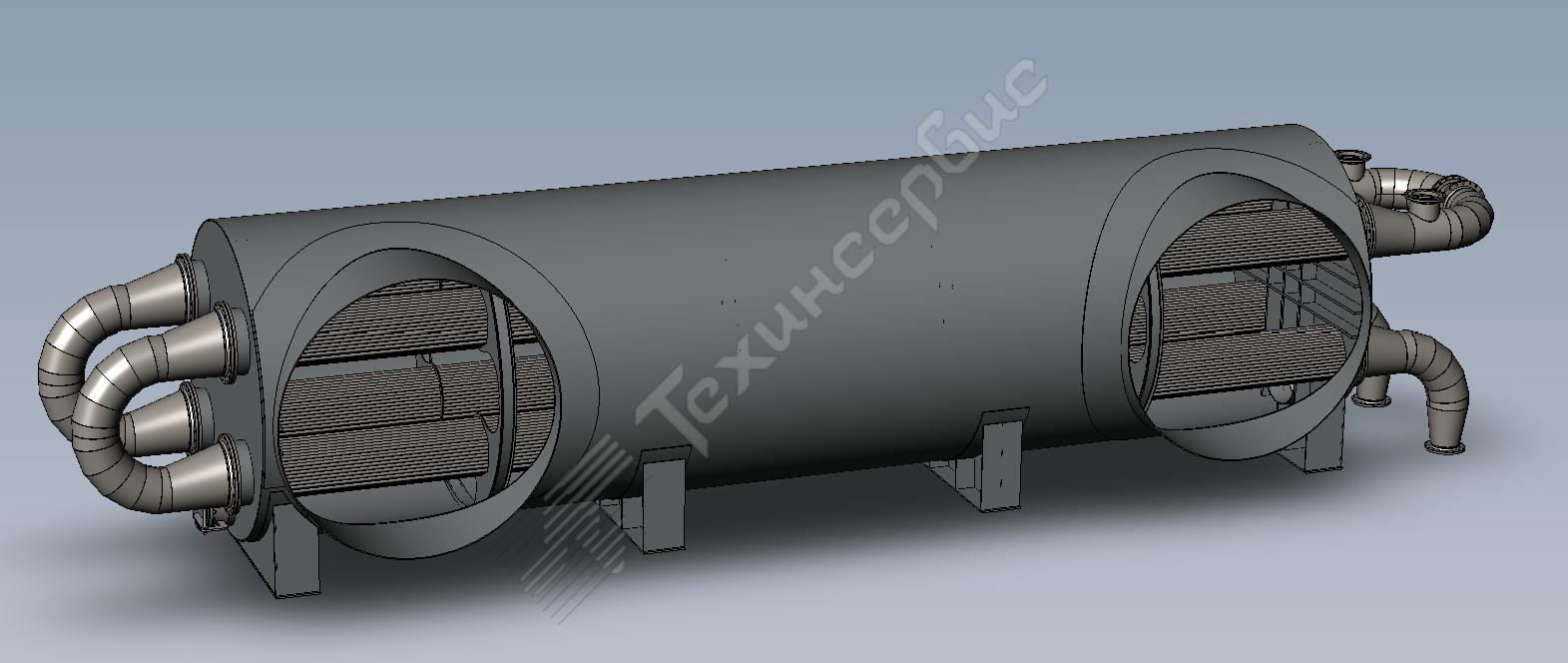

This raw juice heater was delivered in a single-unit capacity. Its length is 17.8 m, weight – 43 tons.

Engineering model of TPDU raw juice heater

Engineering model of TPDU raw juice heater

Heat-exchange surface is 1236 m2.

The period of design, manufacture and delivery of the heater according to the Customer’s specific requirements encompassed 2 months.

Shipment of raw juice heater at Grebinky Machine-Building Plant

Shipment of raw juice heater at Grebinky Machine-Building Plant

Installation was carried out under the supervision of highly qualified specialists of Techinservice. The whole process of massecuite heater installation took just 1 hour. The lifting height – 25 meters.

Installation of raw juice heater at the refinery in Uelzen, Germany

Installation of raw juice heater at the refinery in Uelzen, Germany

Mounted raw juice heater

Mounted raw juice heater

Having installed the Techinservice raw juice heater, the Customer can enjoy the following advantages and benefits, namely:

– reduction in the factory’s total heat consumption due to the use of low-grade massecuite vapour (secondary steam of vacuum pans) for heating;

– minimum level of scale formation due to the high speed of product and as a result the reduction in maintenance operations;

– long life cycle (over 15 years) without serious repairs thanks to the unique design of a heater steam body, which ensures a minimum destructive effect of steam flow on tube bundles;

– remote control unit; no need in operators.

This heater is manufactured in accordance with all relevant directives of the European Union (CE) and Germany (AD2000) as well as certified by the international Certification Authority TÜV Rheinland.

Raw juice heater mounted at the Nordzucker refinery

Raw juice heater mounted at the Nordzucker refinery

Techinservice is the only one Ukrainian engineering company that manufactures and supplies its own high-quality equipment to the leading companies of the EU sugar market.

The Techinservice equipment is successfully operated at the well-known European sugar factories in Bulgaria, Poland, Latvia, Lithuania, Slovakia, Serbia, Hungary and the Czech Republic.

This shipment of Techinservice equipment to Germany proves that Ukrainian companies can compete head-to-head with the leading European manufacturers of sugar industry equipment and expand their product sales territories worldwide.

Reference: Uelzen sugar factory belongs to the German sugar giant Nordzucker AG, the second largest sugar producer in Europe. This factory is the largest refinery of the Group and produces around 50 per cent of Nordzucker retail sugar.

It’s worth mentioning that in 2010 Techinservice successfully shipped four raw juice heaters to Nordzucker AG sugar factory in Clauen, which produces high-quality crystalline white sugar in bulk form for industrial customers, and in 2006 two PDU-230 raw juice heaters for Mátra Cukor sugar factory, Nordzucker’s subsidiary in Hungary.

Also in 2005, three sugar refineries of Nordzucker AG in Serbia got the following equipment made by Techinservice: Vrbas sugar factory – vacuum condensing unit (VCU), two PDU raw juice heaters, two BGV-600 cooling towers (which were installed on the roof of the existing factory building) and automatic control system for VCU; Pećinci sugar factory – VCU, two PDU raw juice heaters and automatic control system for VCU; and Kovačica sugar factory – two PDU raw juice heaters, automated VCU and blocks liquid distribution units for existing fan cooling towers.

|

|

Nordzucker sugar factory in Uelzen

Українська

Українська Русский

Русский