The belt drier is designed for drying of bulk materials at sugar factories and other industrial enterprises. Its operation principle is based on the high-efficient technology of using low-grade heat of secondary energy resources and exhaust gases. If this drier is installed at the sugar plant, heat of the recirculating system of water cooling towers.

By using the belt drier it is possible to:

1. utilize the plant’s recirculating system potential, which is irrecoverably wasted in water cooling towers;

2. reduce the overall power consumption by water cooling towers (or to shut off several blocks of cooling towers);

3. increase the capacity of the existing drying section without modernization of existing driers by means of extensive use of the potential of exhaust (mixture of flue gases with moisture evaporated in the drier) from existing gas driers.

The distinctive feature of this drier is that the heat potential of exhaust wet flue gases from existing driers is transferred in a heating condenser to the enterprise’s recirculating system water, which when reaching the temperature of 65-75 0C serves as a heat-transfer medium for heating the atmospheric air coming into the low temperature dryer.

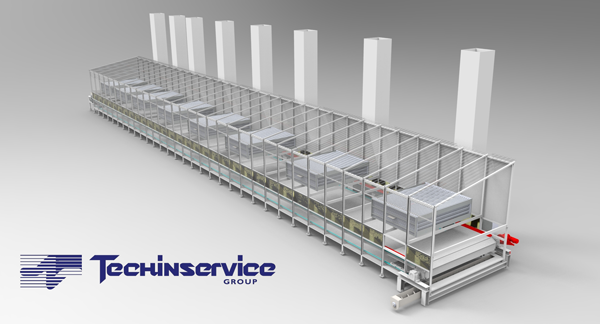

The belt dryer is composed of such main unit as transportation system, air feeding and heating system as well as system for loading and distributing material over the belt.

Continuous dry cleaning and intermittent wet drying are used to clean the belt drier.

Belt Dryer Technical Data:

|

Capacity on evaporated moisture |

18.33 |

|

Inlet pulp consumption, t/h |

73.3 |

|

Inlet pulp moisture, % |

76 |

|

Outlet pulp consumption, t/h |

55 |

|

Outlet pulp moisture, % |

68 |

|

Temperature of heat-transfer medium (circulating water heated by exhaust fumes from the existing gas drier), 0C |

68 |

|

Heat-transfer medium consumption, t/h |

440 |

|

Belt dimensions: |

|

|

Width, m |

6 |

|

Useful length, m |

115 |

This invention is officially patented by Techinservice.

Українська

Українська Русский

Русский