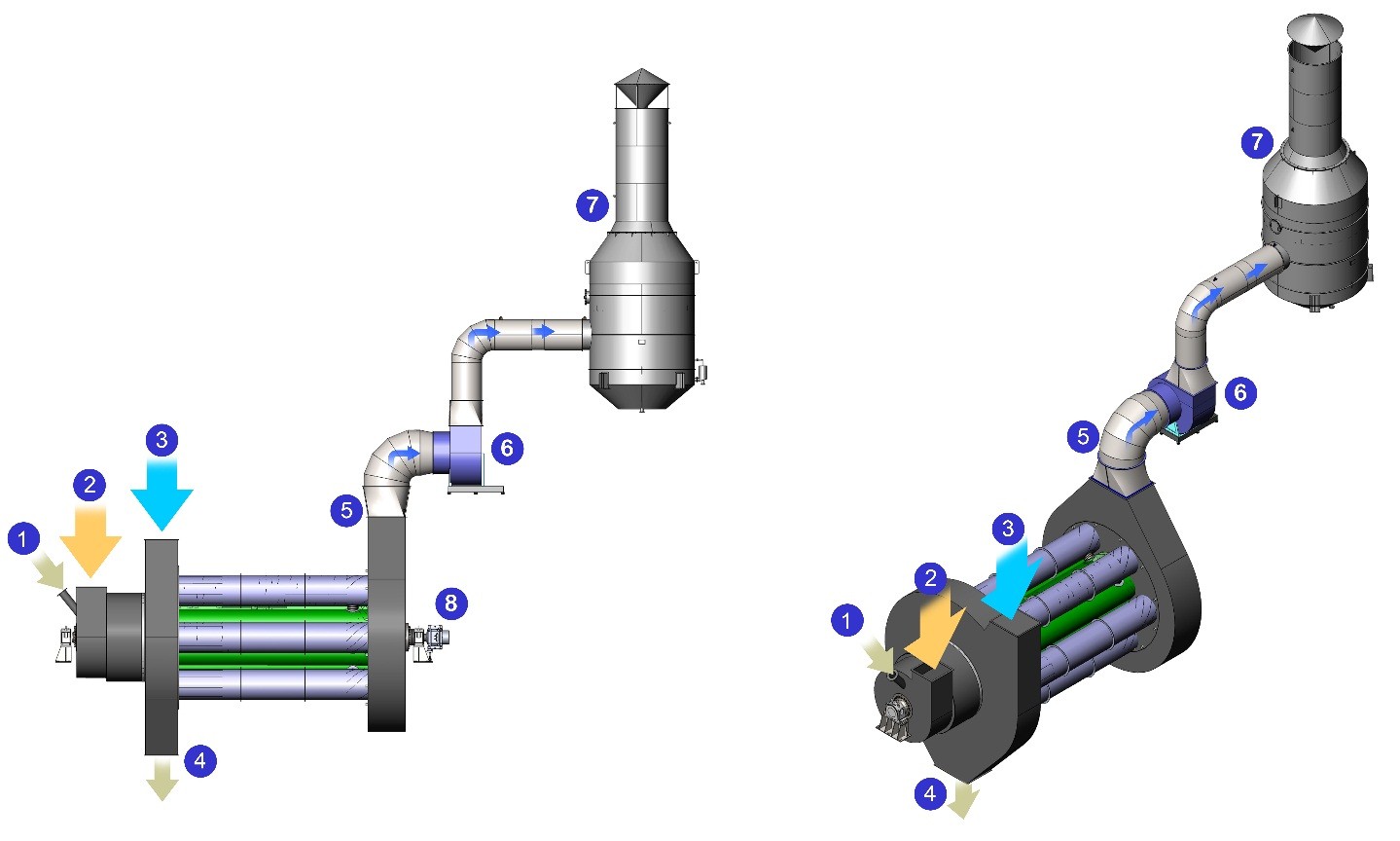

Sugar drying plant mod. TSS60 is designed for drying and cooling of white sugar. This plant ensures high-performance and stable drying and cooling processes with low damage of sugar crystals.

It is composed of the following parts:

1 – sugar inlet

2 – hot air inlet

3 – cool air inlet

4 – sugar outlet

5 – mixed air outlet

6 – fan

7 – cyclone

8 – drive

Technical Data:

1) Capacity on dry sugar, t/h – 60

2) Diameter of 6 drying tubes, mm – 1120

3) Diameter of 6 cooling tubes, mm – -1220

4) Distance between supports, m – 14.1

5) Drive of drying-cooling chamber:

– power, kW – 55

– rotation speed, rpm – 5.8

6) Co-current drying and countercurrent cooling

7) Temperature drop between the inlet cooling air and dry sugar leaving the drier, 0C, not more than – 15

8) Residual moisture, %, not more than – 0.07

Upon the Client’s request, Techinservice can design and manufacture the following models of the drier with the capacity of 30-100 tons of sugar per hour.

|

Model |

Capacity (tons of sugar per hour) |

Drying tube diameter (mm) |

Cooling tube diameter (mm) |

Distance between supports (m) |

|

TSS40 |

40 |

920 |

1020 |

14.1 |

|

TSS50 |

50 |

1020 |

1120 |

14.1 |

|

TSS60 |

60 |

1120 |

1220 |

14.1 |

|

TSS80 |

80 |

1220 |

1320 |

15.5 |

|

TSS100 |

100 |

1320 |

1620 |

15.5 |

Українська

Українська Русский

Русский