The carbonation tank is a part of the complex of equipment for lime/carbonic acid juice purification in the sugar production process.

The carbonation tank is a part of the complex of equipment for lime/carbonic acid juice purification in the sugar production process.

The carbonator is designed for adsorption of raw juice nonsugars on the calcium carbonate precipitate and for precipitation of calcium carbonate with good filtration properties.

The carbonator features a circulating tube fitted below with a bubble section made of gas distribution tubes.

Each gas distribution tube is equipped with a cleaning unit driven by an electric motor.

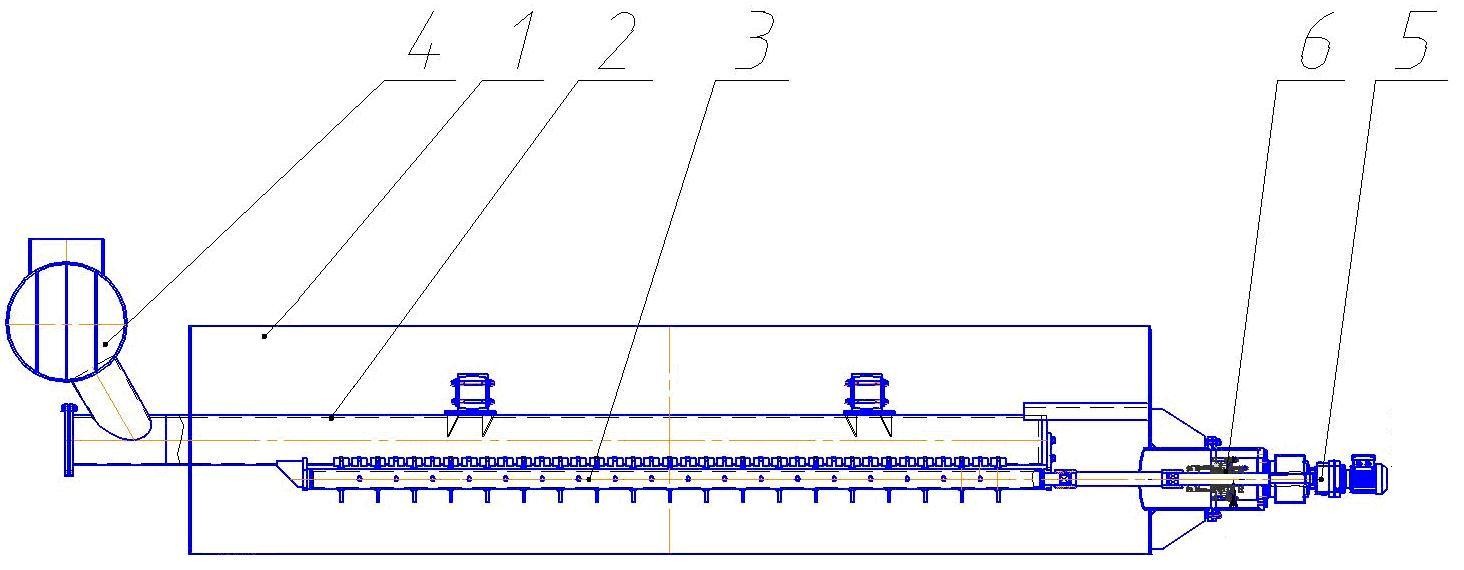

The carbonation tank mod. TS consists of three main blocks cut into separate parts according to transportation and installation, namely:

1 – case

2 – circulating tube

3 – bubble section with gas distribution tubes

Richter tubes (gas distribution tubes) constitute a part of the carbonator bubble section. Bubble section 4 consists of shell 1 and Richter tubes 2 with slits placed in parallel. Outside the shell the tubes are joined by common gas inlet manifold 4. Slits are kept continuously clean by scrapers mounted on shaft 3 placed under the bubble tube. Each shaft has its own motor-reducer 5. The shaft entry is sealed with stuffing box 6.

Techinservice MG also provides customized installation, start-up & commissioning and automation services for all types of juice and syrup purification equipment in accordance with technical requirements of our Clients.

Українська

Українська Русский

Русский